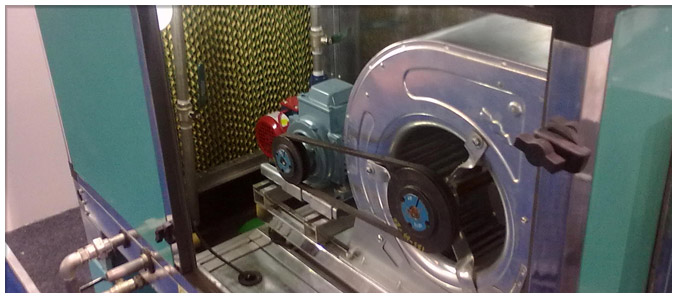

Humidification Systems / Air Washer Unit

Principle of Operation

Fresh air is drawn through air intake louvers and then made to pass through a battery of pre filters. This filtered air then further passed through a battery of fine filters where it gets filtered up to 95% Filtration efficiency down to dust particle of 5 microns. This fresh and filtered air is then passed through air washer section. When an air stream is brought into contact with water, the water will evaporate which will remove heat from the air stream. The heat from the air is absorbed by the water, and the water is mixed with the air and loses its heat to water and in turn gets cooled. Fresh, filtered & cooled air is supplied to the room by centrifugal blowers through air conveyance ducting and supplied air grills. This air then removes equipment heat load and maintains desired ambient conditions in the equipments.

Cooling pads

The cooling pads utilized in evaporative air coolers provide sufficient water-to-air contact area to promote water evaporation. The cooling pad materials commonly in use are Aspen wood and Cellulose pad. Aspen wood pad is a package of thin shredded wood slivers having a thickness of 3 to 5 cm and the material is spread equally over the pad-holder surface. Cellulose cooling pads are made from specially impregnated and corrugated cellulose paper sheets with two different flute angles. These sheets are bonded together alternatively with one steep sheet and one flat sheet. Most medium/large evaporative air coolers in India use Cellulose pads.

The efficiency of Cellulose pads varies from 70% to over 95%, depending upon the thickness of the pad and air velocity. It can last up to 10 years or more

Maintenance

Regular maintenance of the pads is important to ensure the evaporative air conditioners operate efficiently for many years. Manufacturers recommend that both sides of the pads should be gently washed to remove the built up salts, dust and pollen. The pads should be replaced if they are in poor condition. The maintenance can be done annually either before or after the cooling season.

Technical data

• Air velocity through washer 2.5 m/s

• Water pressure required for spray nozzles 140 - 170 kN/m2

• Water pressure required for flooding nozzles 30 - 70 kN/m2

Advantages

• Coolers are economical to operate, using one-third the energy of refrigerated air-conditioning.

• Cooler maintenance and repairs can be accomplished by the User.

• Cooler’s replacement parts (pads, belts, etc.) are nominal in cost when compared to air-conditioning system replacement parts.

• Coolers bring fresh, cooled, outside air into the home.

• Coolers provide a healthy environment for plants.